When you remove the front panel, the filament, the tension pulley and the spring become a clean unit.

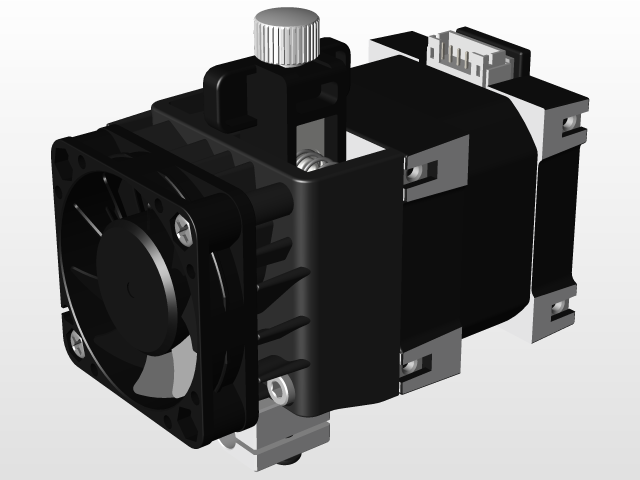

#Hemera volcano full

Full access allows parts to be cleaned and replaced even when filament is loaded. If you need to disassemble Hemera for maintenance, you can easily access the internal mechanisms by removing the fan and loosening the two screws on the front panel. The filament tension is increased by turning it clockwise and reduced by turning it counterclockwise. You can see the brass tubes with the resin printed duct cooling material from the volcano here: BerdAirNozzle.jpg. To adjust the filament tension, the user simply turns a knurled screw and a cam slide mechanism with a captive nut compresses a spring and loads the tensioning pulley. On a more serious note, all of the Print Heads I have designed so far are using a BerdAir system which consists of an air pump pushing air to the small prongs each side of the nozzle via a tube. The interaction with Hemera is from above. The design of the Hemera heat sink ensures that airflow is directed up and away from both the Hot end and the heated bed, reducing the risk of warping and uneven tension in the printed part. hemera nozzle Genuine E3D Volcano Block for Sensor Cartridges. Hemera offers practical T-slots for easy mounting on your printer as well as space for additional accessories, part fans and bed levelling probes. e3d hemera heat block Genuine E3D Hardened Steel Nozzle V6 (1.75mm) 0.40mm (V6-NOZZLE. This exceptional system also has a significant impact on the printing of rigid and semi-rigid materials such as PLA or nylon. Only when you print ultra-flexible materials can you experience the full extent of filament delivery and reliability. Hemera extrudes filaments like no other extrusion system. CNC machined from stainless steel, this heat break takes filament from the hobbed gear output, out of the cold side and feeds it directly into the nozzle melt zone of the chosen hotend. The Antarctic volcano seems to retell the Greek drama with each long season. This heat break is the link between the v6, Volcano, and SuperVolcano heater blocks and the dual-drive performance of the Hemera extruder.

#Hemera volcano install

to install slots and produce a very compact system.įilament extrusion like no other extruder Erebus' daughter Hemera dispersed the mists at dawn, bringing daylight. It has a custom motor based on a NEMA17, as well as its own faceplate design, which allows the user to be more comfortable, e.g. The secondary gear shaft is located on a movable, sprung idler wheel that allows the user to adjust the filament tension.Į3D Hemera is a system of components that work together seamlessly as a single compact product. In fact, filaments can be pushed with up to 10 kg of force. But after a good 12 hours of making test prints, Ive finally got.

It combines the market-leading V6 hot end with a brand new filament drive to create a responsive direct drive extrusion system that offers unprecedented performance with flexible filaments.įor E3D Hemera, E3D opted for a dual drive arrangement made of hardened stainless steel, which offers enormous grip compared to single drive systems. The biggest problem is the 1.0mm E3D-V6 Volcano nozzle leaving blobs all over the place. The E3D Hemera - formerly Hermes - is the best extrusion system that E3D has ever manufactured.

0 kommentar(er)

0 kommentar(er)